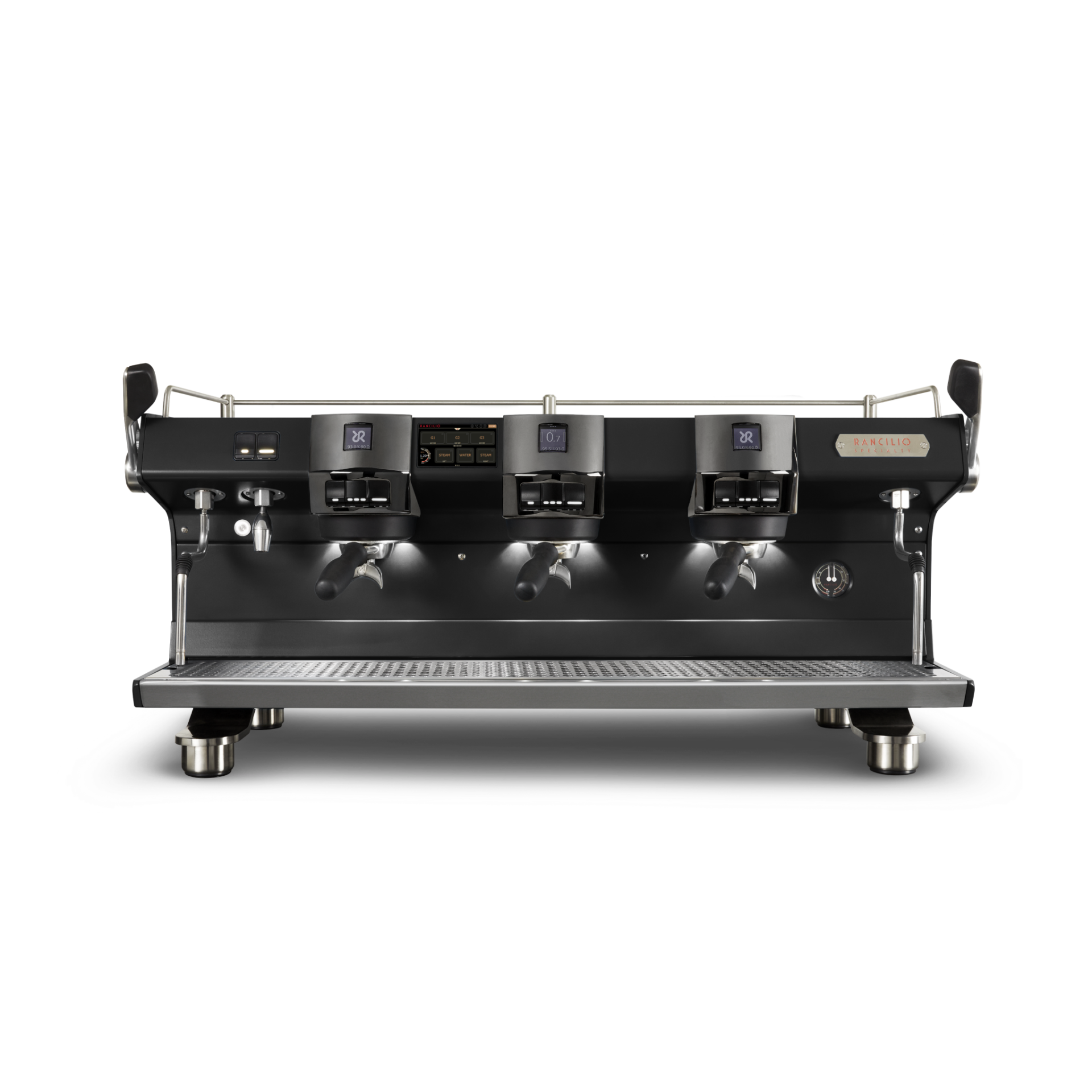

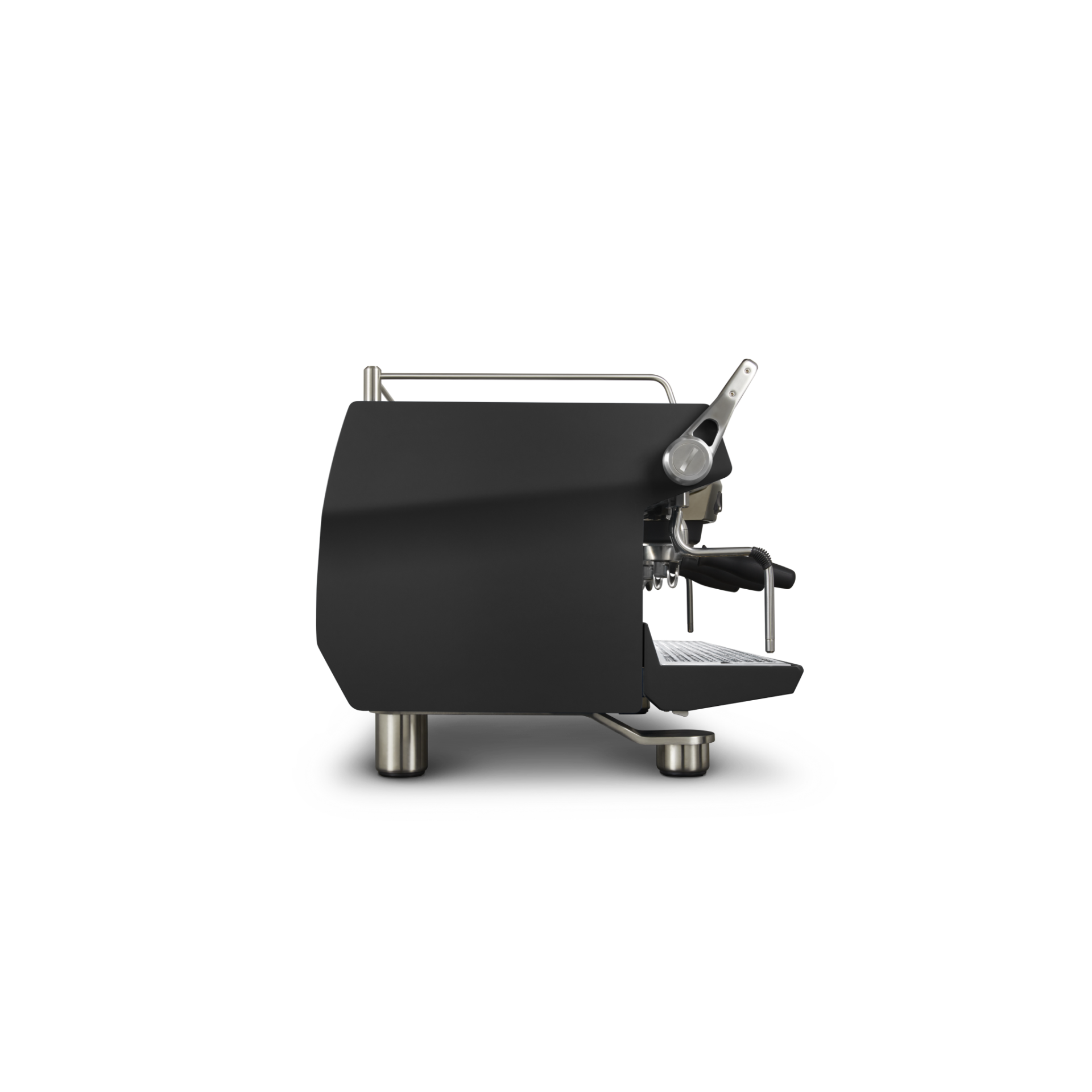

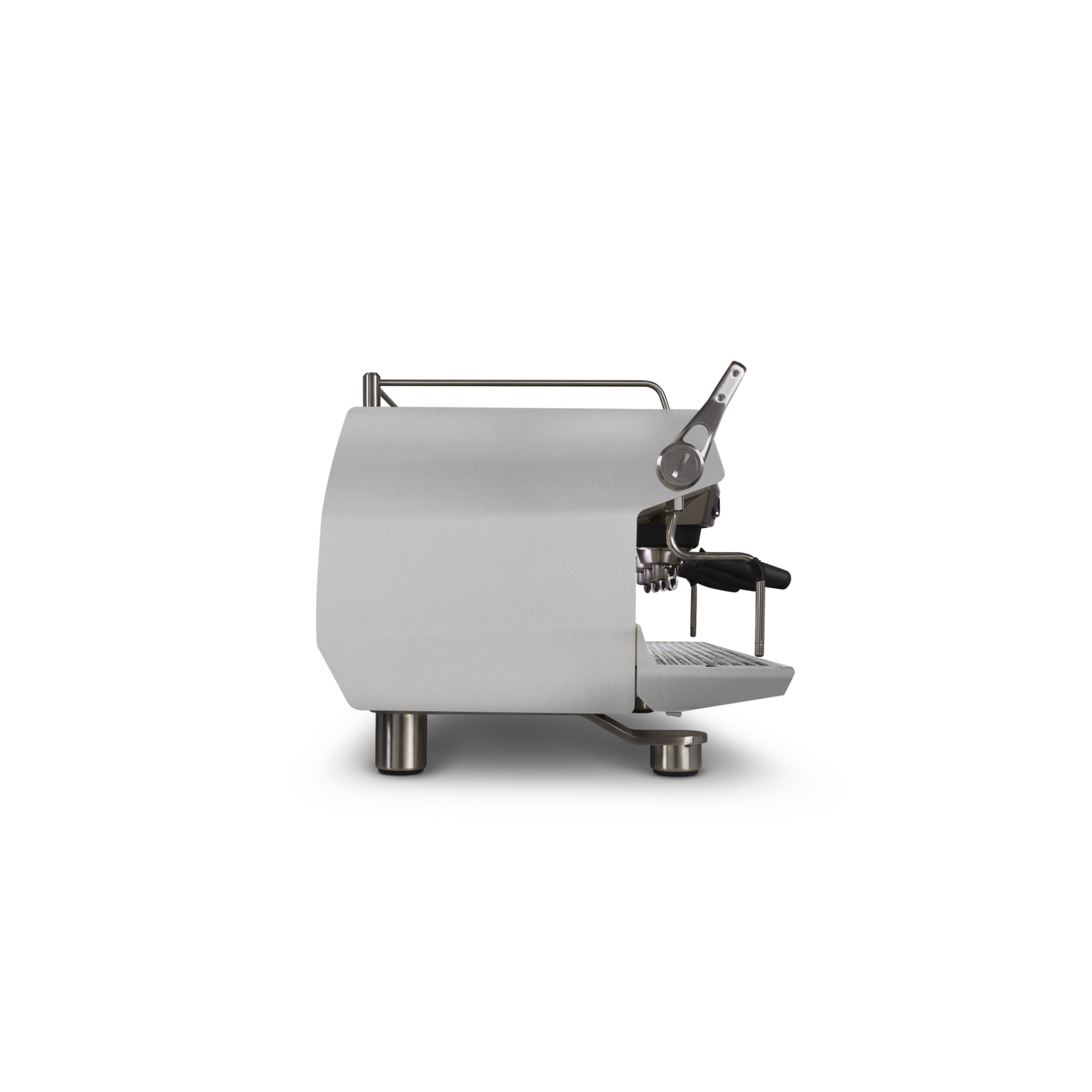

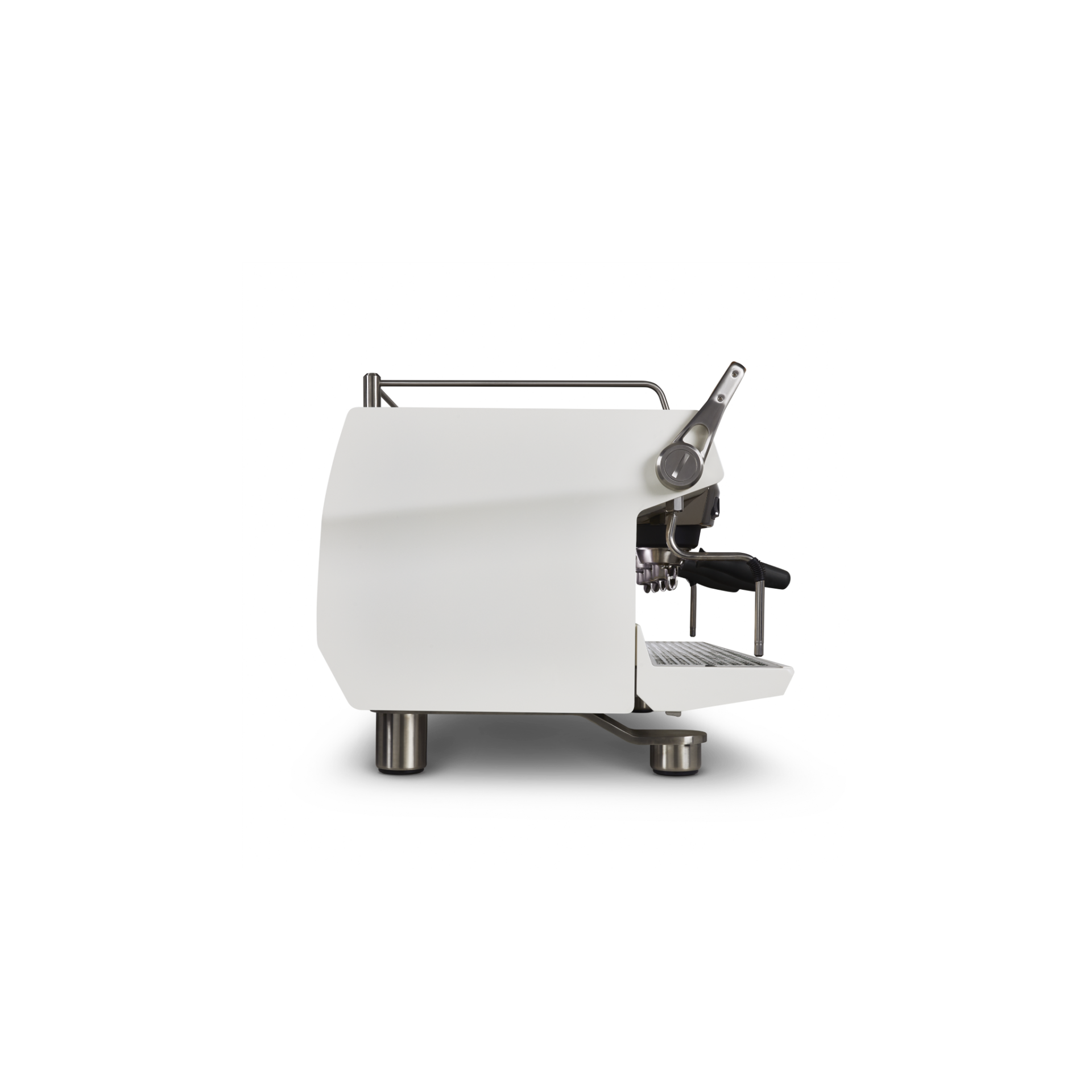

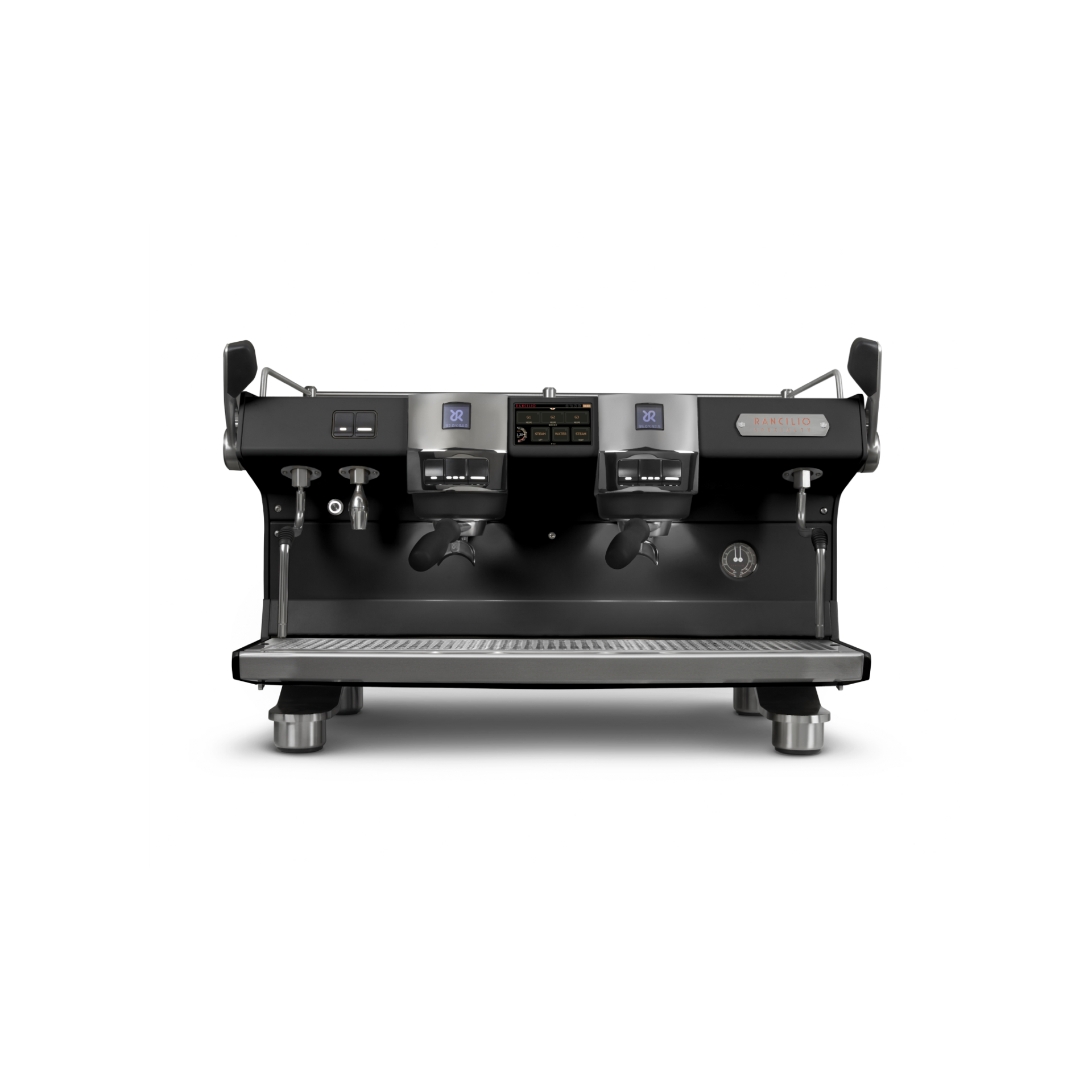

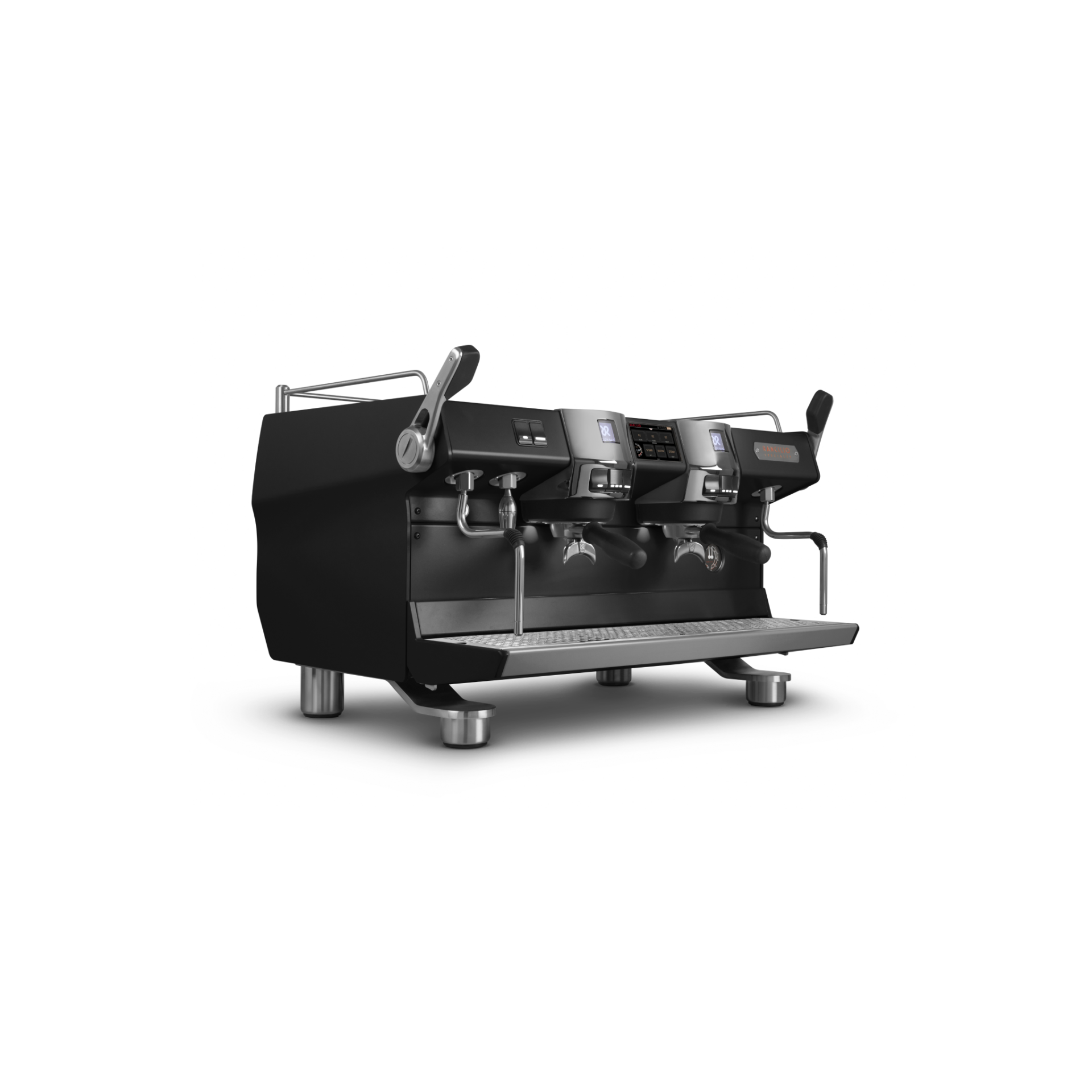

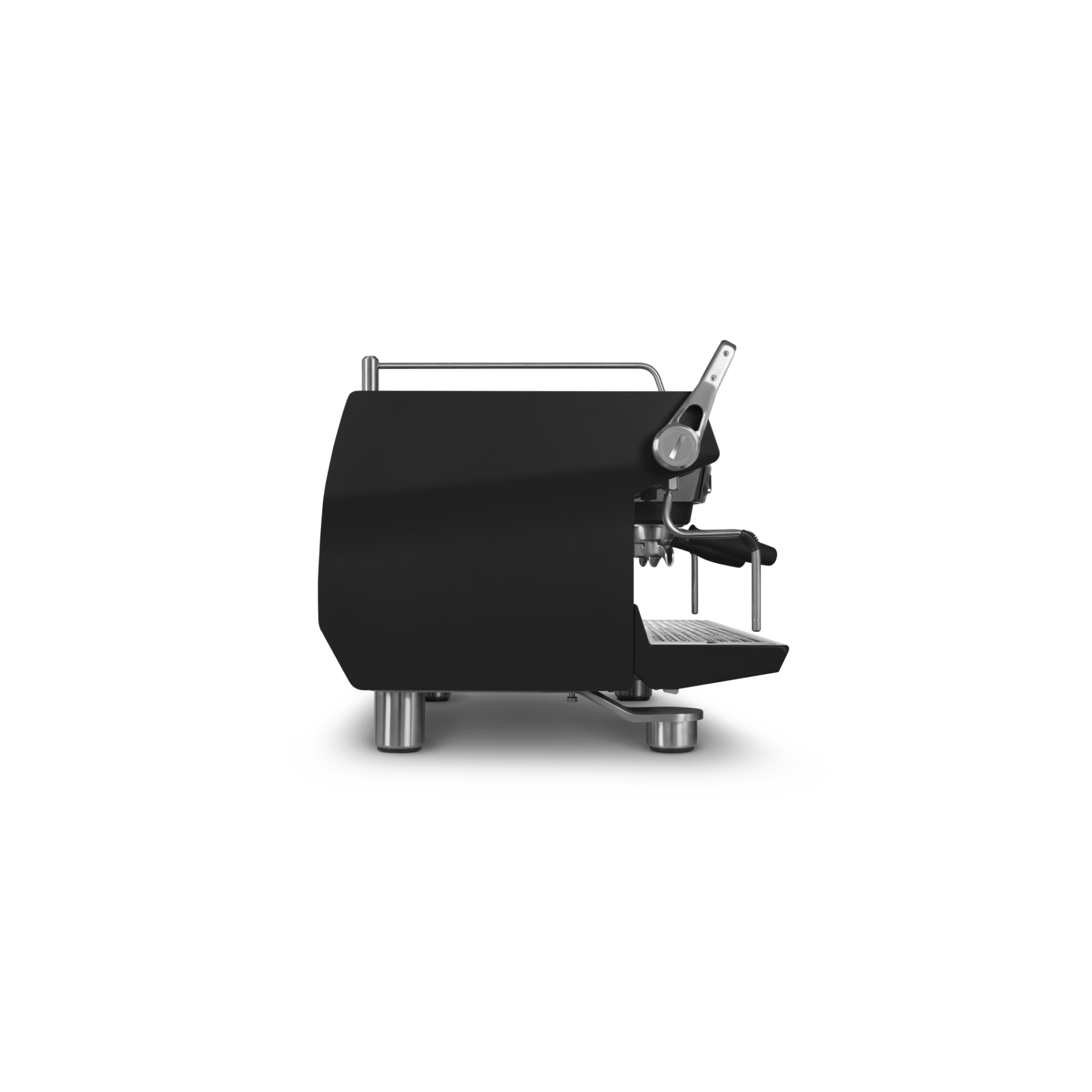

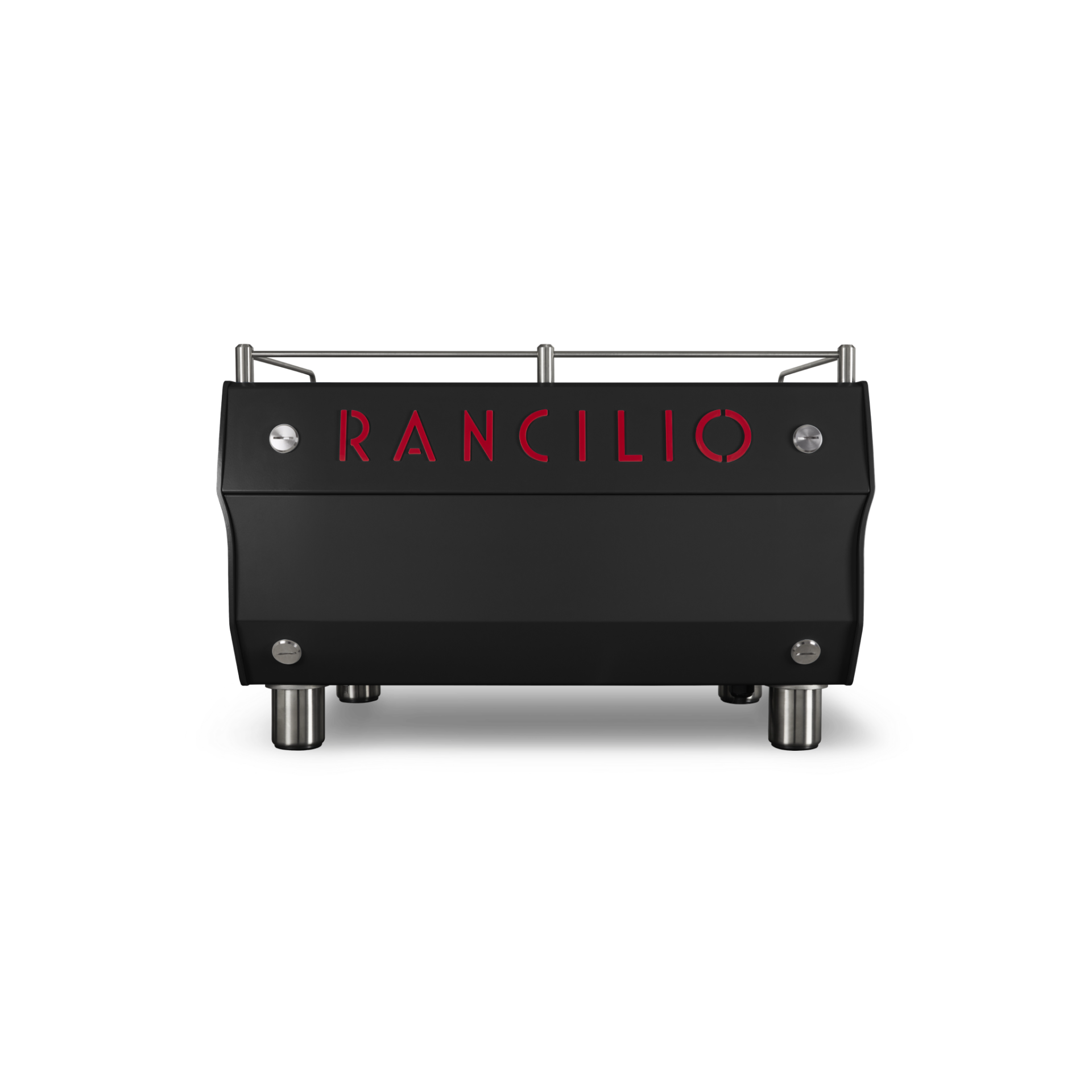

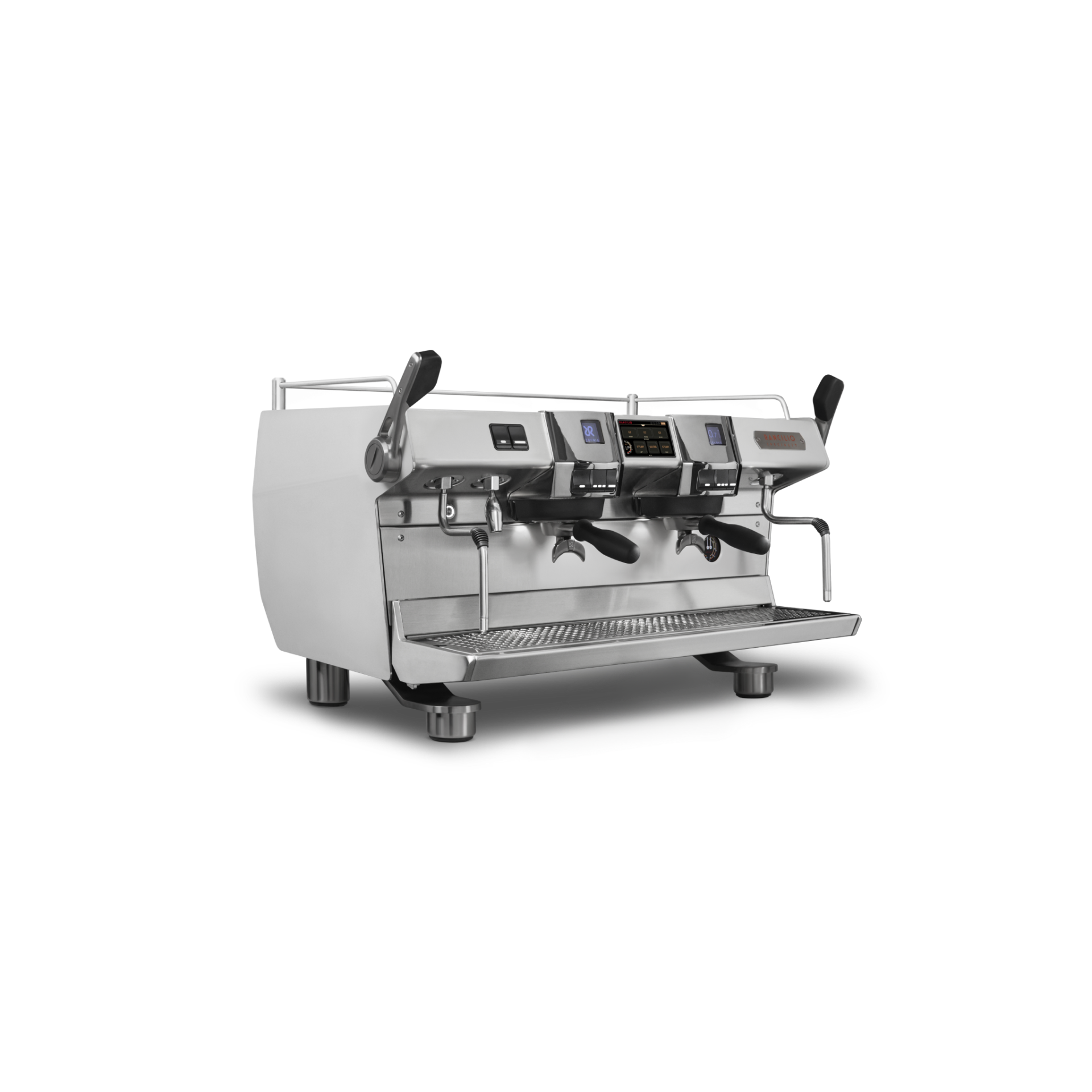

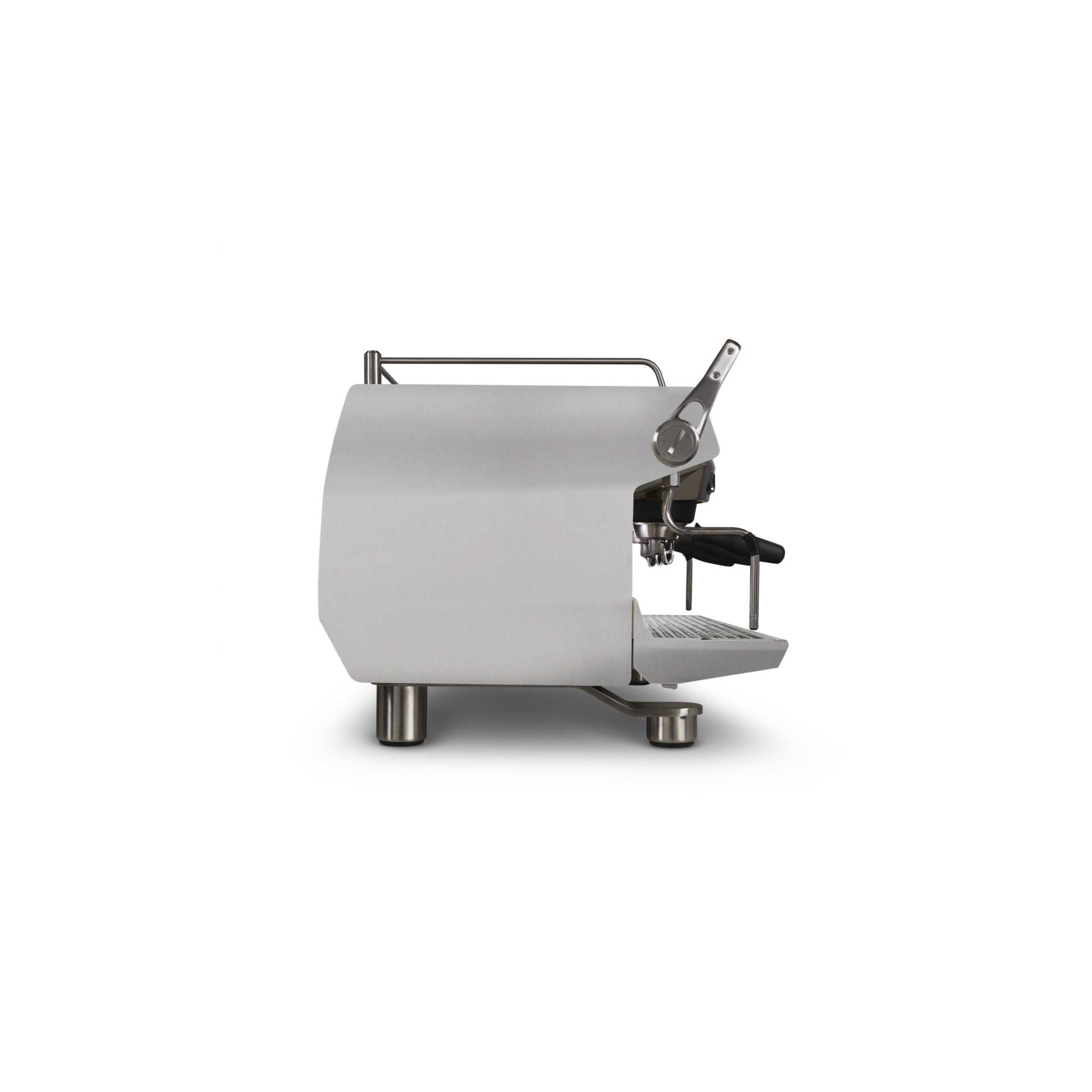

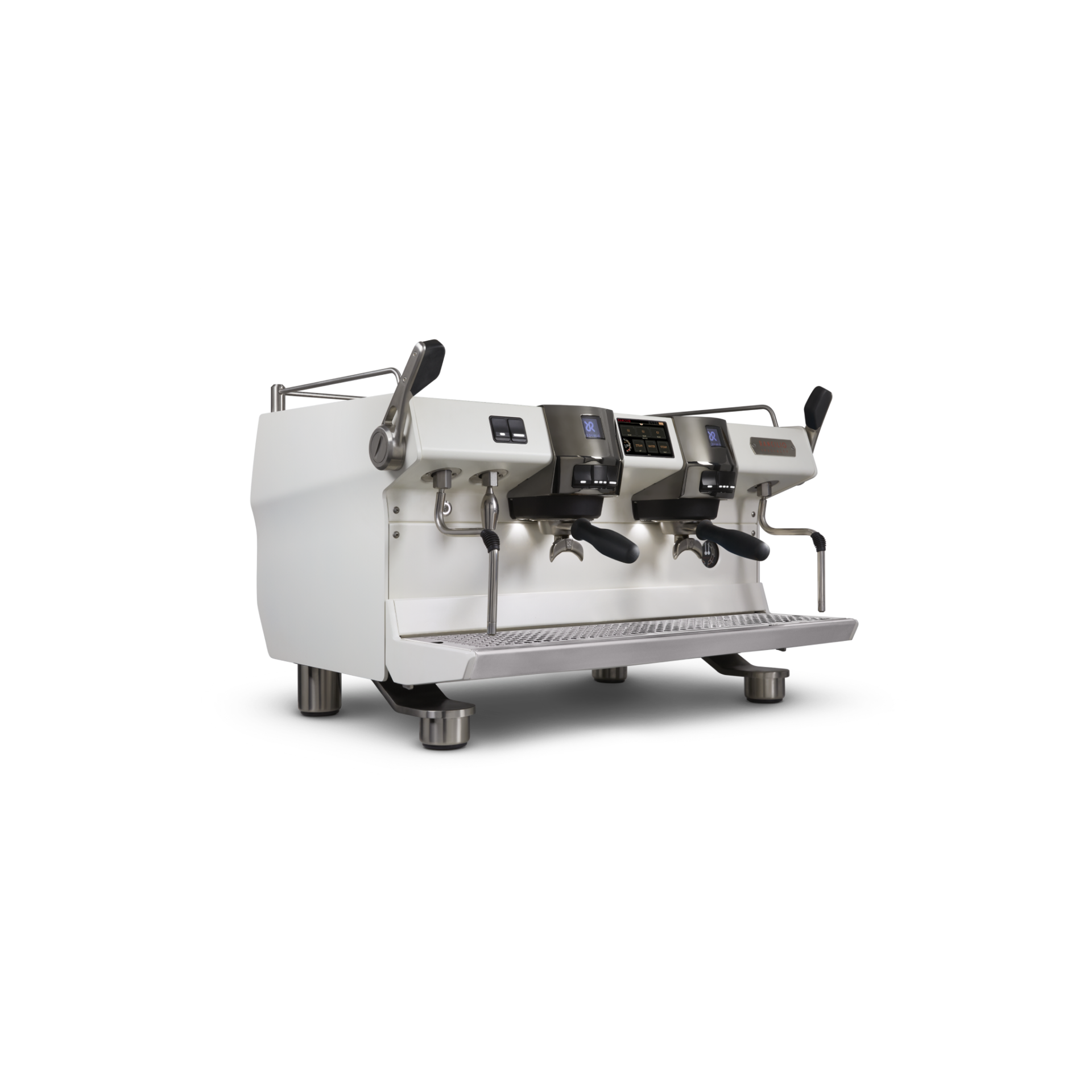

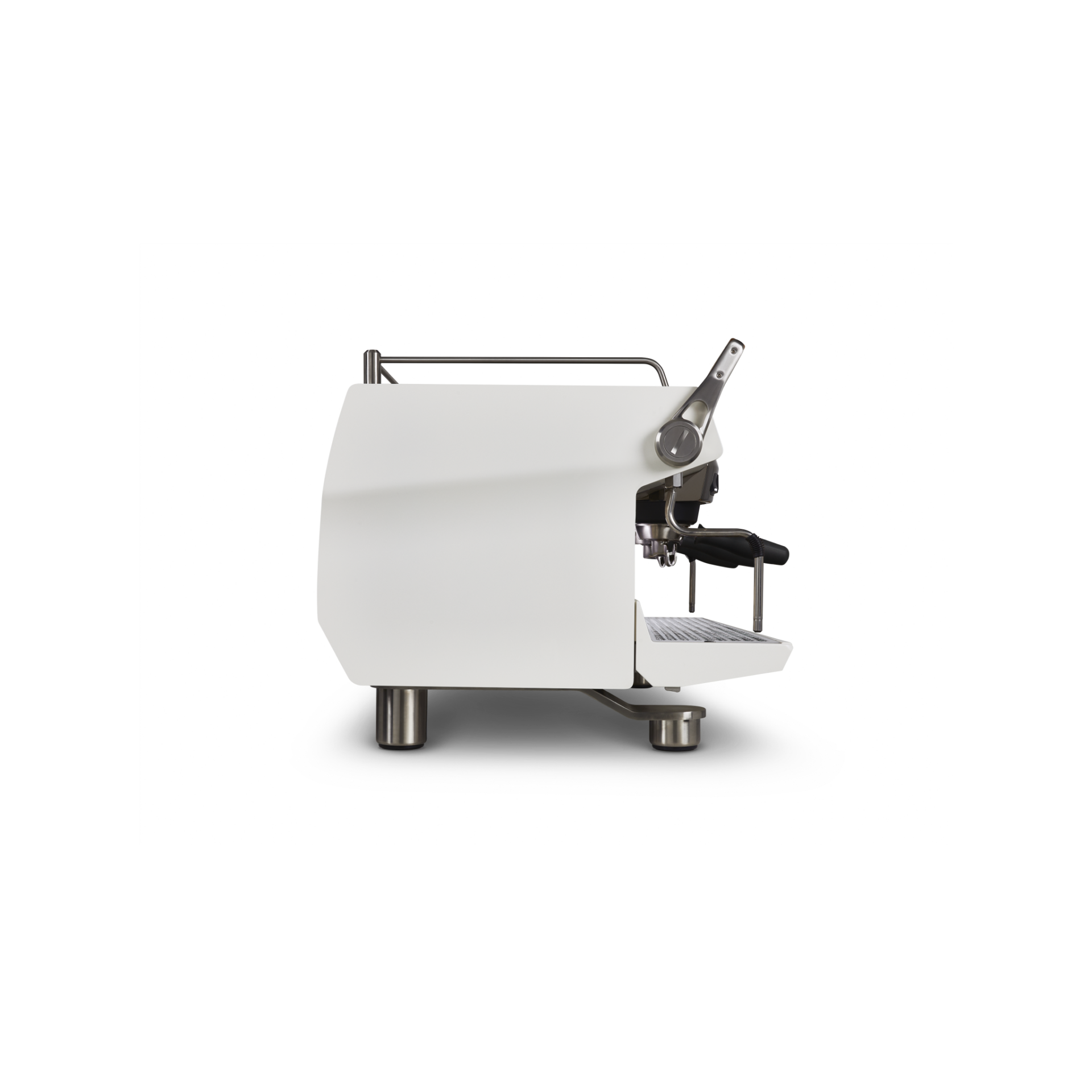

RS1

Multi-boiler espresso machine available in 2 or 3 groups with automatic dosing, Advanced Temperature Profiling technology, pre-infusion and post-infusion.

| Variations |

|

|---|---|

| Version | Automatic |

| Version | Automatic |

| Colors |

|

| Colors |

|

Technical specifications

-

Standard

-

Optional

Dimensions

- 1084 mm / 42,67 inch

- 463 mm / 18,23 inch

- 600 mm / 23,62 inch

- 110 kg / 242,5 lb

- yes

- 120 mm / 5 inch

Interface and operations

-

Grouphead display

- 4.3''

- Per group

Brewing technology

-

Advanced Temperature Profiling

Thanks to Advanced Temperature Profiling technology, baristas can increase or decrease the temperature of the water dispensed during espresso extraction by up to 5°C (9°F). By accurately controlling the temperature profile of the espresso extraction, baristas are given a precise tool to unlock the flavour potential of each single-origin coffee or blend. The Advanced Temperature Profiling system differs from the Xcelsius Temperature Profiling system due to the steel group head – which offers greater reactivity than the brass group – a micro-boiler with a higher thermal capacity (with a 300W heating element), and the presence of an additional 40W adhesive heating element on the front of the group. Compared to the performance offered by Xcelsius Temperature Profiling, this system provides a further reduction in the variability of the actual temperature as compared to the preset temperature (2σ), as well as an even faster response to the temperature profiling required by the barista. Rancilio Patented Technology.

-

Multi-boiler system

Each independent group is equipped with a micro-boiler and a heating element. As well as keeping the temperatures of both the water and the group stable, the multi-boiler system improves the thermal performance of the machine, even when simultaneously brewing espresso and steaming milk, and allows different temperatures to be set for each group head.

-

Pre-infusion and Post-infusion

The barista can vary the water pressure both in the initial stage (pre-infusion) and in the final stage (post-infusion) of the extraction process, choosing between mains pressure or pump pressure, and also adjust the duration of all stages (pre-infusion, extraction, post-infusion).

- Stainless steel

Water

-

Hot water wand

-

Smart Flush

By activating the Smart Flush function, the duration of the flush varies according to the time elapsed since the last coffee delivery. This function keeps the group at the right temperature and improves thermal stability.

-

X-Tea

Baristas can programme water dosages and temperature levels via the interface.

Rancilio Patented Technology

Steam

-

Cool touch steam wand

The cool touch steam wand is thermally insulated with a double-layered protective coating.

-

Variable steam lever

Steam lever with a “Purge” function and two positions for steam delivery, each adjustable to different powers: perfect for switching between various jug sizes and different types of milk.

Power

- 220-240 V~ / 380-415 V3N~ , 50-60 Hz 6750W

- Fixed water connection

Hydraulic circuit

- 16 l

- 0,15 l

Design

-

LED lights

White LED lights positioned under the group heads provide excellent illumination for the work area.

-

Stainless Steel Ergonomic Portafilter

Counterweighted stainless steel portafilter with a soft-touch, ergonomic grip, designed to ensure excellent stability when tamping.

Green

-

ABM

ABM is a specific software developed to improve the performance of the machine in conditions of intensive use. When simultaneously brewing espresso, dispensing water and steaming milk, ABM switches on the heating element to pre-empt any drops in pressure under the preset value, thus preventing drops in temperature to ensure constant heating levels.

Control of the boiler pressure is optimised in the case of the intensive and simultaneous use of multiple group heads. In these cases, in order to prevent the pressure from dropping below a minimum value of 0.5 bar, ABM can stop water from being dispensed until the boiler pressure returns to a suitable level.

ABM also allows for control of the machine’s power consumption, reducing it to 2/3 of the normal value where power availability is low.

For espresso machines equipped with the iSteam wand, ABM also improves steam delivery performance by increasing the power of the heating element in the boiler, allowing it to produce more heat and reduce drops in pressure during milk frothing.

Rancilio Patented Technology -

Auto ON-OFF

It is possible to set the automatic on and off times for the machine (Classe 11, Classe 20) or set the automatic on time and the power-on hours (Classe 9, Classe 7) for each day of the week.

-

Eco Mode

By managing the different water levels in the boiler, the water-to-steam ratio can be optimised to achieve maximum energy savings. In low usage conditions, the quantity of water in the boiler is reduced, thus increasing the proportion of steam. Working with less water in the boiler allows for lower energy consumption in order to bring it to the ideal temperature. And, at the same time, with more steam and less moisture in the boiler, the performance of the steam wands also improves.

Cleaning & maintenance

-

Advanced Diagnostics

Thanks to the Advanced Diagnostic system, technical intervention times are reduced to a minimum. The “Technical” menu includes a “Service” function allowing users to test all the machine’s systems, to simply tap on the interface to check all components are in good working order, and to pinpoint faults or technical problems without having to inspect internal elements.

-

Easy clean

The group cleaning and rinsing cycles are automatic and can be activated from the touchscreen. A daily alarm can be set to remind users to activate the cleaning cycle. It is also possible to set the optional machine block if cleaning does not take place and display the history of all actions performed.

-

Grid System

-

Hydro Hub

-

Snap&Share

Snap&Share is a QR code reader app that allows users to share the technical settings of their espresso machine, keep track of maintenance operations, monitor consumption, and register new products to activate the warranty.

-

USB

Additional Optionals

-

Connect

Connect is a powerful IoT solution developed by Rancilio Group, to gather and easy analyze all the value relevant data generated by a single coffee machine or an entire fleet. Via a customizable dashboard with widgets, tables and graphs, Connect gives you a ready to use digital toolkit, to monitor key performance parameters in real time and empower your whole coffee business.

-

Cup Warmer

The cup warmer keeps all espresso and cappuccino cups at the right temperature at all times.

-

Wood Kit

Dimensions

- 840 mm / 33,07 inch

- 463 mm / 18,23 inch

- 600 mm / 23,62 inch

- 95 Kg / 209,4 lb

- yes

- 120 mm / 5 inch

Interface and operations

-

Grouphead display

- 4.3''

- Per group

Brewing technology

-

Advanced Temperature Profiling

Thanks to Advanced Temperature Profiling technology, baristas can increase or decrease the temperature of the water dispensed during espresso extraction by up to 5°C (9°F). By accurately controlling the temperature profile of the espresso extraction, baristas are given a precise tool to unlock the flavour potential of each single-origin coffee or blend. The Advanced Temperature Profiling system differs from the Xcelsius Temperature Profiling system due to the steel group head – which offers greater reactivity than the brass group – a micro-boiler with a higher thermal capacity (with a 300W heating element), and the presence of an additional 40W adhesive heating element on the front of the group. Compared to the performance offered by Xcelsius Temperature Profiling, this system provides a further reduction in the variability of the actual temperature as compared to the preset temperature (2σ), as well as an even faster response to the temperature profiling required by the barista. Rancilio Patented Technology.

-

Multi-boiler system

Each independent group is equipped with a micro-boiler and a heating element. As well as keeping the temperatures of both the water and the group stable, the multi-boiler system improves the thermal performance of the machine, even when simultaneously brewing espresso and steaming milk, and allows different temperatures to be set for each group head.

-

Pre-infusion and Post-infusion

The barista can vary the water pressure both in the initial stage (pre-infusion) and in the final stage (post-infusion) of the extraction process, choosing between mains pressure or pump pressure, and also adjust the duration of all stages (pre-infusion, extraction, post-infusion).

- Stainless steel

Water

-

Hot water wand

-

Smart Flush

By activating the Smart Flush function, the duration of the flush varies according to the time elapsed since the last coffee delivery. This function keeps the group at the right temperature and improves thermal stability.

-

X-Tea

Baristas can programme water dosages and temperature levels via the interface.

Rancilio Patented Technology

Steam

-

Cool touch steam wand

The cool touch steam wand is thermally insulated with a double-layered protective coating.

-

Variable steam lever

Steam lever with a “Purge” function and two positions for steam delivery, each adjustable to different powers: perfect for switching between various jug sizes and different types of milk.

Power

- 220-240 V~ / 380-415 V3N~ , 50-60 Hz 5600 W

- Fixed water connection

Hydraulic circuit

- 11 l

- 0,15 l

Design

-

LED lights

White LED lights positioned under the group heads provide excellent illumination for the work area.

-

Stainless Steel Ergonomic Portafilter

Counterweighted stainless steel portafilter with a soft-touch, ergonomic grip, designed to ensure excellent stability when tamping.

Green

-

ABM

ABM is a specific software developed to improve the performance of the machine in conditions of intensive use. When simultaneously brewing espresso, dispensing water and steaming milk, ABM switches on the heating element to pre-empt any drops in pressure under the preset value, thus preventing drops in temperature to ensure constant heating levels.

Control of the boiler pressure is optimised in the case of the intensive and simultaneous use of multiple group heads. In these cases, in order to prevent the pressure from dropping below a minimum value of 0.5 bar, ABM can stop water from being dispensed until the boiler pressure returns to a suitable level.

ABM also allows for control of the machine’s power consumption, reducing it to 2/3 of the normal value where power availability is low.

For espresso machines equipped with the iSteam wand, ABM also improves steam delivery performance by increasing the power of the heating element in the boiler, allowing it to produce more heat and reduce drops in pressure during milk frothing.

Rancilio Patented Technology -

Auto ON-OFF

It is possible to set the automatic on and off times for the machine (Classe 11, Classe 20) or set the automatic on time and the power-on hours (Classe 9, Classe 7) for each day of the week.

-

Eco Mode

By managing the different water levels in the boiler, the water-to-steam ratio can be optimised to achieve maximum energy savings. In low usage conditions, the quantity of water in the boiler is reduced, thus increasing the proportion of steam. Working with less water in the boiler allows for lower energy consumption in order to bring it to the ideal temperature. And, at the same time, with more steam and less moisture in the boiler, the performance of the steam wands also improves.

Cleaning & maintenance

-

Advanced Diagnostics

Thanks to the Advanced Diagnostic system, technical intervention times are reduced to a minimum. The “Technical” menu includes a “Service” function allowing users to test all the machine’s systems, to simply tap on the interface to check all components are in good working order, and to pinpoint faults or technical problems without having to inspect internal elements.

-

Easy clean

The group cleaning and rinsing cycles are automatic and can be activated from the touchscreen. A daily alarm can be set to remind users to activate the cleaning cycle. It is also possible to set the optional machine block if cleaning does not take place and display the history of all actions performed.

-

Grid System

-

Hydro Hub

-

Snap&Share

Snap&Share is a QR code reader app that allows users to share the technical settings of their espresso machine, keep track of maintenance operations, monitor consumption, and register new products to activate the warranty.

-

USB

Additional Optionals

-

Connect

Connect is a powerful IoT solution developed by Rancilio Group, to gather and easy analyze all the value relevant data generated by a single coffee machine or an entire fleet. Via a customizable dashboard with widgets, tables and graphs, Connect gives you a ready to use digital toolkit, to monitor key performance parameters in real time and empower your whole coffee business.

-

Cup Warmer

The cup warmer keeps all espresso and cappuccino cups at the right temperature at all times.

-

Wood Kit